TEMSR series methanol steam reforming hydrogen production unit is a device that efficiently produces hydrogen from hydrocarbons or hydrogen-containing molecules. Compared with fossil fuels, methanol has the characteristics of a low carbon atom number and a high hydrogen-carbon ratio, which can significantly reduce the generation of by-products such as carbon deposition and CO. Moreover, it is compatible with the basic storage and transportation facilities of the current oil and gas era, featuring high efficiency and economy.

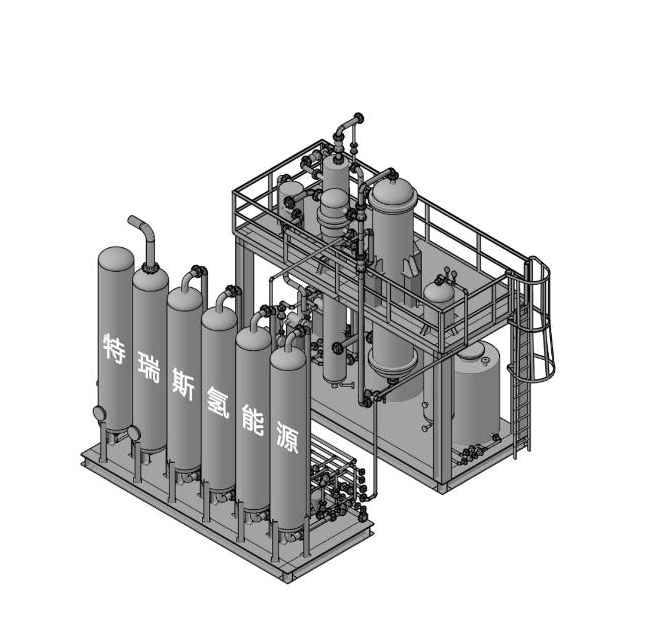

The methanol hydrogen production unit is applicable to various application scenarios such as steel, metallurgy, chemical industry, pharmaceuticals, light industry, building materials, electronics, and on-site hydrogen production at hydrogen refueling stations. According to different hydrogen production capacities, it can be divided into skid-mounted and containerized types.

Methanol steam reforming for hydrogen production involves the catalytic reaction of methanol and steam under appropriate conditions to generate a mixed gas of hydrogen and CO₂. Subsequently, high-purity hydrogen is obtained through pressure swing adsorption. This process requires less investment, causes relatively low pollution, and methanol is in a liquid state at room temperature, which is convenient for storage and transportation.

◆Low investment and low energy consumption

◆Stable operation

◆Small floor area of the device

◆High level of automation

◆Diverse structures

Add: No.22 Yanhe Middle Road, Xinbei District, Changzhou City, Jiangsu Province

Tel: 0519-68951000

Fax: 0519-68951800

E-mail: terrencemarket@terrence.com.cn

Website: http://www.terrence.com.cn